Research & Development

JAXA promotes three research and development programs and a fundamental research program that underpins them.

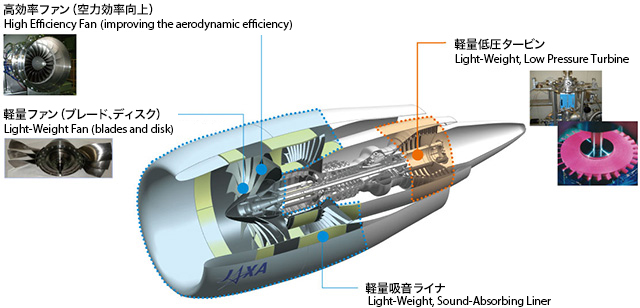

aFJR (Advanced Fan Jet Research) project

Environmental standards for aircraft engines have become tightened as a countermeasure for global warming,and the world's demand for more green engines with better fuel efficiency and low emissions is growing. In the aFJR project, in collaboration with domestic manufacturers, we achieved weight reduction and high efficiency with the world's first hollow composite fan blade and a turbine blade with ceramic matrix composite. We have developed the world's top fuel efficiency reduction technology that exceeds the fuel efficiency reduction target by 70% compared to the latest developed foreign engine.

High Efficiency, Light-Weight Fan Technology

High Efficiency Fan (improving the aerodynamic efficiency)

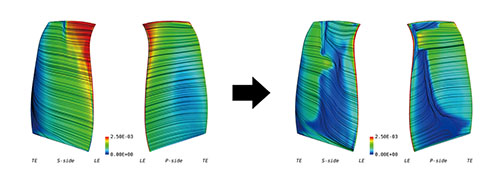

- A prototype rotor blade with a laminar flow design was manufactured and aerodynamic efficiency was verified by aerodynamic performance tests. We also confirmed that flutter prediction CFD is effective for flutter avoidance design of laminar flow fan blades.

Computed Friction Coefficient Distributions on the Blade Surface The application of laminar flow fan technology enlarges the laminar boundary layer region on the blade surface, leading to a lower friction loss and higher efficiency.

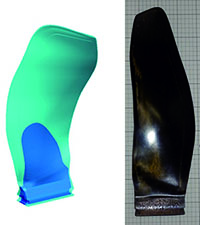

Light-Weight Fan (blades and disk)

- Succeeded in hollowing out carbon fiber reinforced plastic (CFRP) blades and developed lightweight composite fan blade technology. The hollow structure has been realized by improving the damage analysis technology and design manufacturing technology at high speed impact including CFRP laminated structure and metal joint.

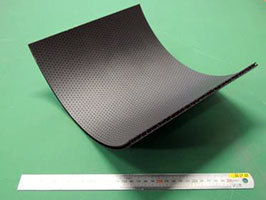

Light-Weight, Sound-Absorbing Liner

- We succeeded in forming a resin sound absorption liner that replaces the existing aluminum sound absorption liner, achieving a weight reduction of 40% or more compared to the aluminum sound absorption liner.

Light-Weight, Low-Pressure Turbine

- We have developed an over-rotation prevention design technology suitable for blades made of ceramic matrix composite (CMC), and demonstrated that it is possible to break CMC blades safely in rotational impact fracture tests.

In order to obtain flutter prediction technology for low pressure turbine cascades, the wind tunnel cascade test measured the flutter generation limit.