About us

JAXA Aviation helps to create a safer and more prosperous society with aeronautics-related research and development activities.

FLIGHT PATH No.23 | 2019 SUMMER

<Aeronautics in depth>

Optical fiber sensors

Having an accurate understanding of strain and damage that an aircraft experiences during flight is very important. JAXA has been developing optical fiber sensor technology to enable this. This page introduces the details of the technology successfully demonstrated in the "High performance Optical fiber sensor flight Tests for AirpLane Wing (HOTALW)" project.

Capturing changes in wavelengths as a “plane”

JAXA has been developing a distributed strain measurement system using optical fiber sensors (OFDR-FBG system). To measure strain in an aircraft, an elaborate sensor system is needed to detect loads and stresses acting on various locations of an aircraft. However, conventional strain gauge sensors measure strain only at the points where they were attached, requiring numerous devices and a complex network of cables. On the other hand, optical fiber sensing is capable of measuring strain at multiple points using only one fiber. By installing multiple optical fibers all over an aircraft, much like the nervous system of a living organism, it is possible to create a system that can monitor the status of an aircraft in planes.

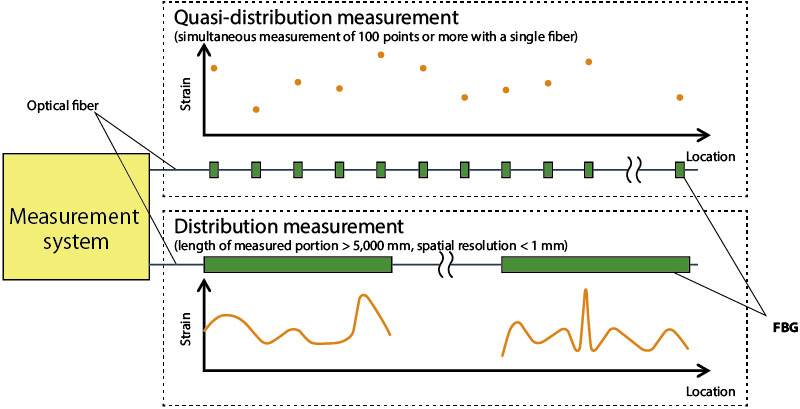

High-performance strain measurement using Optical Frequency Domain Reflectometry - Fiber Bragg Grating (OFDR-FBG), which can monitor strain in a structure in detail. Quasi-distribution measurement of 100 points or more (above) and high-performance distribution measurement of a spatial resolution of 1 mm or less (below)

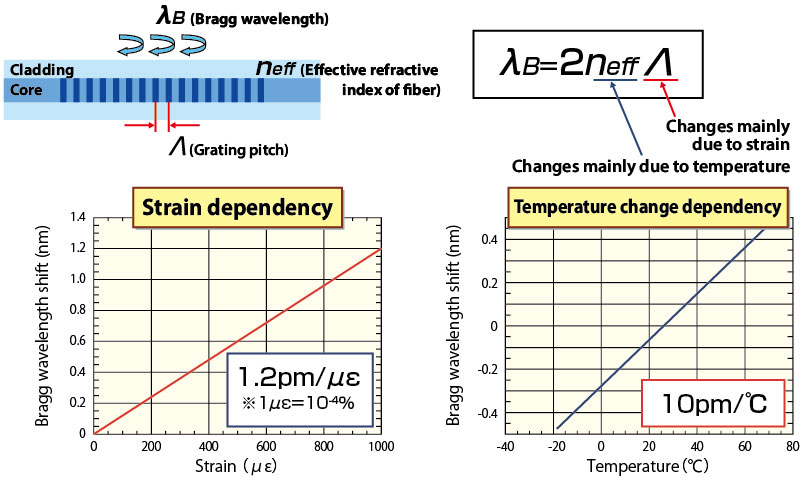

Numerous Fiber Bragg Grating (FBGs) built into optical fibers correspond to sensor devices, and they are arranged in striped patterns spaced at 0.5-μm pitches with slightly different refractive indexes. Light entering the fibers is slightly reflected at the stripes where the reflective indexes of the FBGs change, and returns to the point of incidence. Since reflection occurs only when the light wavelength corresponds to the pitch of stripes, the wavelengths of reflected light will shift when the pitch of the sensor’s stripes changes. JAXA developed an Optical Frequency Domain Reflectometry (OFDR) technology for measuring stress and deformation by continually monitoring the amount of a shift in the wavelengths of reflected light.

FBG-based sensing; gratings expand or contract according to strain in components, causing changes in the wavelengths of reflected light

Real-time data obtained in HOTALW tests using “Hisho”

In the HOTALW test conducted in 2017 using “Hisho,” JAXA’s jet research aircraft, to demonstrate technology for detecting strain in an aircraft with optical fiber sensors, JAXA attached two optical fiber sensors on the lower surface of the wings to verify capabilities under actual flight conditions. The system used in the test had been continually refined since 2009 and is capable of measuring strain at multiple points with a spatial resolution (measurement pitch) of 1.6 mm and temporal resolution of 151 Hz (151 measurements per second), covering a length of 26.5 m. As a result, the test produced data that largely corresponded with conventional strain gauge measurements and values obtained through theoretical analyses. Furthermore, the test demonstrated the system’s excellent response and ability to provide real-time data when executing turns and other maneuvers.

HOTALW test performed using “Hisho” jet research aircraft (above), optical fiber installed inside the aircraft (yellow line indicated with a red arrow)

This technology has the potential to realize a spatial resolution of 1 mm or less, and if costs were not an issue, the measurement distance can be extended as well. The temporal resolution can also be improved if computation and data roaming speeds can be increased through further development effort. The key technological accomplishment in HOTALW is the completion of a highly operable sensor system capable of demonstrating full temporal and spatial resolution performance over the entire measurable length. Compatibility with actual operation is even more important than specifications, and the recent test has shown the direction for future research.

Detailed data measured during flights will be used to achieve weight reduction and other improvements in future aircraft. Real-time monitoring of the aircraft state contributes to maintenance and inspection as well as efficient operation.

Similar sensor systems are being developed overseas as well, but JAXA is a global pioneer in this cutting-edge field as it was the first to successfully demonstrate the technology with an actual business jet.