Research & Development

JAXA promotes three research and development programs and a fundamental research program that underpins them.

En-Core (environmentally compatible core engine technology research) project

- September 14, 2021

- Unprecedentedly Low NOx Emissions Engine [JAXA's No.84]

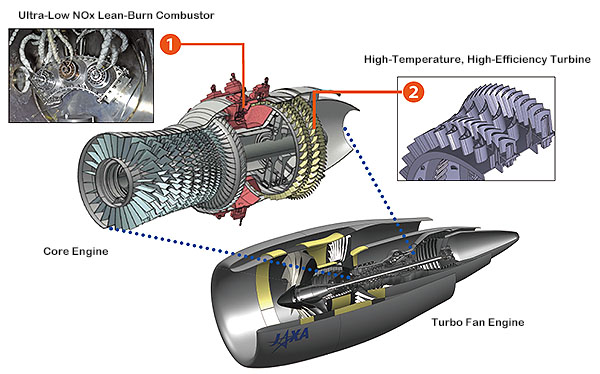

The power for turbo fan engine propulsion is generated by core engine. World's major jet engine manufacturers dominate the production of core engines, especially high-temperature, high-pressure parts such as combustors and high-pressure turbines. Getting its share would be a leap for Japanese manufactures which already have a good share in low-pressure parts. JAXA started a new project which aim to obtain competitive technologies to reduce NOx (nitrogen oxides) and CO2 (carbon dioxide). The project name “En-Core” represents an Environmentally compatible Core engine.

En-Core is a 6-year R&D project until FY2023. It consists of two major targets, “Ultra-low NOx Lean Premixed Combustor” and “High-temperature, High-efficiency Turbine” technology developments. The usage of CMC (ceramic matrix composite) will be the key technology which reduce the cooling air usage in both targets.

Ultra-Low NOx Lean-Burn Combustor

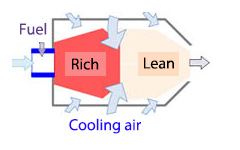

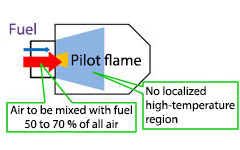

Most combustors in the latest aviation engines adopt the RQL (Rich-burn/Quick-quench/Lean-burn) combustion method. The RQL method reduces NOx emissions while stabilizing combustion, but further reductions of NOx emissions appears difficult under this current method. JAXA has been studying the lean-burn (=lean premixed combustion) method for less NOx emissions than the RQL one. Lean-burn is combustion that takes place with a mixture ratio where the amount of fuel is small compared to that for complete combustion. The En-Core project aims to demonstrate combustor performance with the lowest NOx emissions in the world. Increasing the combustion air by reducing the cooling air using the CMC is a key for realizing the ultra-low NOx lean-burn combustor, as well as the suppression of combustion oscillations. Technologies for practical combustors, such as the thermal management of fuel nozzles and fuel control, will also be developed.

RQL combustor

Lean-burn combustor

High-Temperature High-Efficiency Turbine

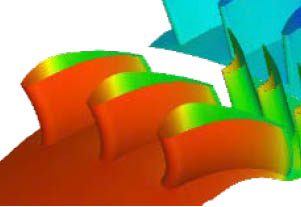

The competitive higher efficiency is the target of the turbine technology development. The smaller usage of cooling air and the 3D aerodynamic design will be integrated to reduce the losses. CMC with higher heat resistance by about 200 deg. C than the latest superalloy, the advanced cooling structures, and various aerodynamic designs will be incorporated.

CMC Stator Vane Design Technology

- Using the Ceramic Matrix Composites (CMC), which have higher thermal resistance than the currently applied superalloy, losses caused by cooling air will be reduced.

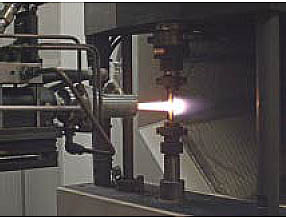

Film Cooling Technology

This technology will reduce mixing losses by high-temperature gas flows around the high-pressure turbine and coolant air ejected through the blade cooling holes.

Blade Internal Cooling Technology

Cooling air necessary for the high-pressure turbine will be reduced by adopting the internal cooling structure that has higher cooling effects.

Loss Reduction by 3D Aerodynamic Design Technology

- By utilizing computational fluid dynamics (CFD), 3D design technologies will be applied to reduce aerodynamic losses on the surface of the blades.

March 31, 2020