Innovative Green Aircraft Technology (iGreen)

Topics

There has been an increasing need for greener aircraft with less CO2 and NOx emission and less noise amidst the global challenge faces aviation community such as global warming and the tightened regulations on noise around airport. In such a situation, the technological development to improve the competitiveness on economic and environmental capabilities is necessary to further increase market share for Japanese aviation industry.

To design airframe that have higher environmental performances, JAXA launched a research named “Innovative Green Aircraft Technology (iGreen)” in FY2020. Based on the findings of the R&D of “Eco-wing technology”, the iGreen project will identify and mature unique technologies with competitive edges for drastic improvements in the environmental performances of future aircraft application. While the aerodynamics aspects of the iGreen research are addressed under the work package named High Efficiency and Low Noise Aircraft(HELNA) by the Aviation Systems Research Units, the structural aspects of the research will be led by the Structures and Advanced Composite Research Unit under the work package named Bionic Airframe.

Goals and objectives

The purpose of the iGreen research is to develop and mature a bunch of advanced and innovative technologies on aerodynamics, aeroacoustics, and structures to enable airframe design with higher environmental performances, thereby helping the Japanese aviation industry to enhance its share on the global market. In addition to verifying practical application of these technologies, we will also work on the development of elemental and system technologies.

- Identifying unique technologies with competitive edge and mature them to the higher technological readiness level for practical passenger aircraft application, which will help enhance the international competitiveness of Japanese aviation industry.

- Developing key technologies that enable drastic improvements in the environmental performances of future aircraft with less CO2 emission and airport noise, which will eventually help the Japanese aviation industry to make shift to the new business model to play a key role in the international joint development project.

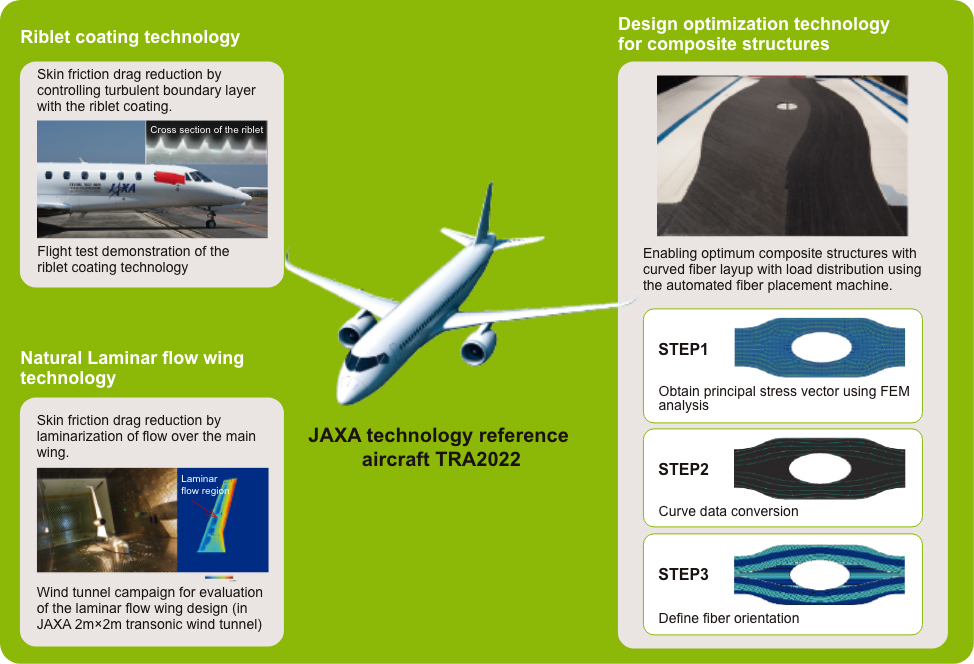

iGreen technologies for near-term implementation

To improve fuel efficiency by reducing aerodynamic drag and structural weight, we are working on the skin friction drag reduction technologies such as the riblet coating technology and the natural laminar flow wing design, as well as the optimal design and manufacturing technologies to enable light-weight composite structures. Ground tests and flight tests will be conducted to evaluate the environmental performances of the developed technologies.

■Riblet coating technology

Taking into consideration of the actual operational environments and requirements of passenger aircraft, we are examining the way to improve the durability of riblet coating and the practical methods for applying the riblet coating on larger surface of aircraft. We are also looking into the patterns and shapes of the grooves of the coating for further improvements in the drag reduction effect.

■Natural Laminar flow wing technology

We will identify and develop the best possible wing shape that enable laminarization of the wing to reduce skin friction drag. The laminar wing design technology will be validated by a series of wind tunnel tests at actual flight conditions, while also developing numerical analysis technologies and design technologies. We are also working on the skin quality and coating materials to keep the laminar flow regions over the wing. This is because the skin quality defines the specification of the surface roughness on manufacturing, and the coating prevents flow contamination caused by the pollutants at take-off and landing.

■Design optimization technology for composite structures

To enable light-weight composite structures, we are working to develop optimal design of tow steering placement technology that enables curved lay up of fibers with optimal distribution of internal loads and thickness, using the automated fiber placement machine.

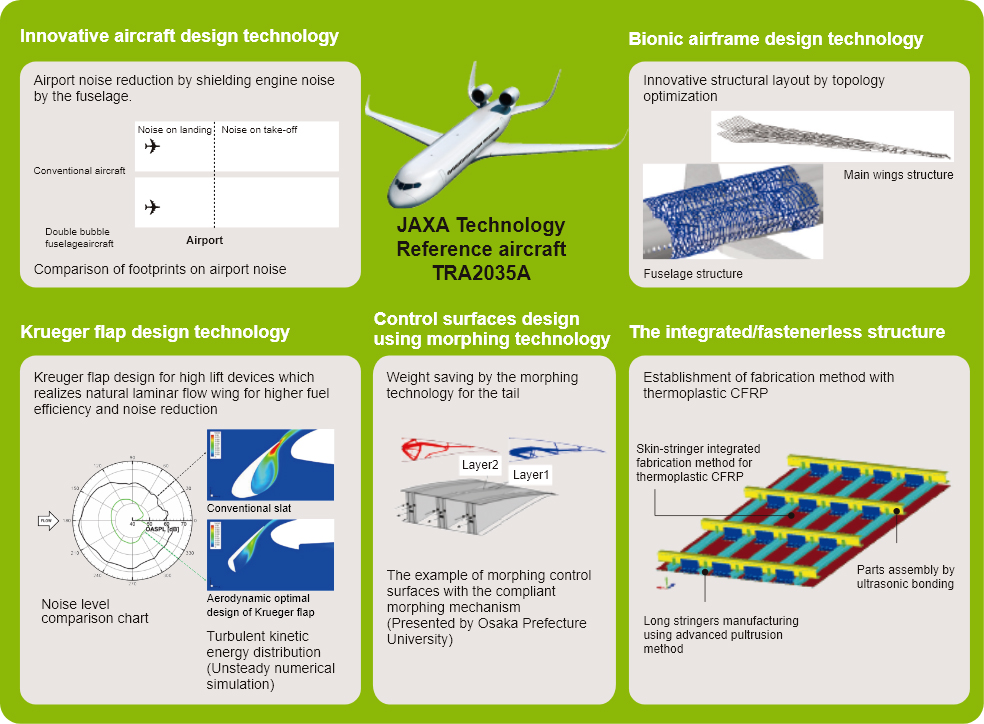

iGreen technologies for future aircraft

We are also advancing studies on innovative airframe technologies with an eye on future aircraft which will enter into service in the 2040s. To enable significant improvements in reducing fuel consumption and airport noise, we are addressing studies relating aerodynamics and structures as well as developing design technologies to enable future aircraft configurations proposed through the studies.

■Aerodynamic designs technologies for future aircraft

We are studying elemental technologies for future aircraft. Research themes include the studies on innovative airframe configuration to significantly reduce airport noise by engine mounting over the rear fuselage so that engine noise is shielded with fuselage and tails; Krueger flap design technology to realize natural laminar flow wing for higher fuel efficiency and noise reduction; and the Morphing technology for the tails and control surfaces.

■ Structural technologies for future aircraft

We are conducting the R&D of elemental technologies, such as bionic airframe technology to design the best optimized structure for aircraft using topology optimization methods applying the approach of biomimetics that mimics creature’s bone structure; skin stringer integrated fabrication method for thermoplastic CFRP; and fastenerless structures for reduction of manufacturing cost.